INDUSTRY SECTORS

SPECIALITY & FINE CHEMICALS

MolSep™ Opportunities in Specialty & Fine Chemicals

- Maximizing reaction yield in condensation reactions like esterification, amidoamine synthesis etc. by in-situ removal of water using Pervaporation or Vapor permeation

MICROELECTRONICS, BATTERIES & SOLAR

MolSep™ Opportunities in Microelectronics, Batteries & Solar

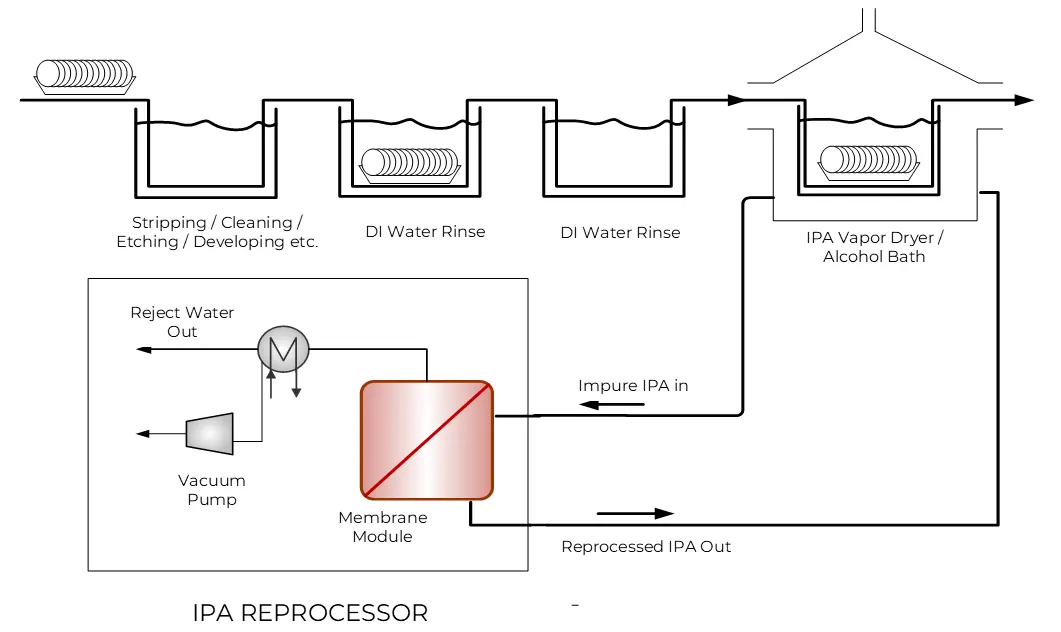

In microelectronics industry (hard disks, displays, optoelectronics and semiconductors), battery manufacturing and solar, large quantities of solvents such as IPA, NMP, TMAH, Photoresist stripping solvents, Hydrofluoric Acid etc. are used for vapor drying, cleaning, degreasing, etching and other operations during manufacture. In particular, Isopropyl Alcohol (IPA) is used in bulk by the electronics industry in the manufacturing of semiconductors, flat panel displays, disks, opto-electronics, and other electronics components. IPA used gets contaminated with moisture, metallic impurities, and organic impurities due to drag-out from prior processing steps. Our IPA Reprocessor may be integrated in-line in a Point-of-Use Solution or waste IPA from various lines may be collected and processed in a Central Solution.

We also have solutions for NMP drying, TMAH formulations drying, Hydrofluoric Acid recovery (removal of Fluosilicic Acid & trace metallic impurities), Photoresist stripping solvent recovery.

BIOFUELS

MolSep™ Opportunities in Biofuels Manufacturing

Bioethanol is growing rapidly for fuel-blending to produce green fuels. Additionally, other alcohols – such as Mixed alcohols and Butanol are gaining favor.

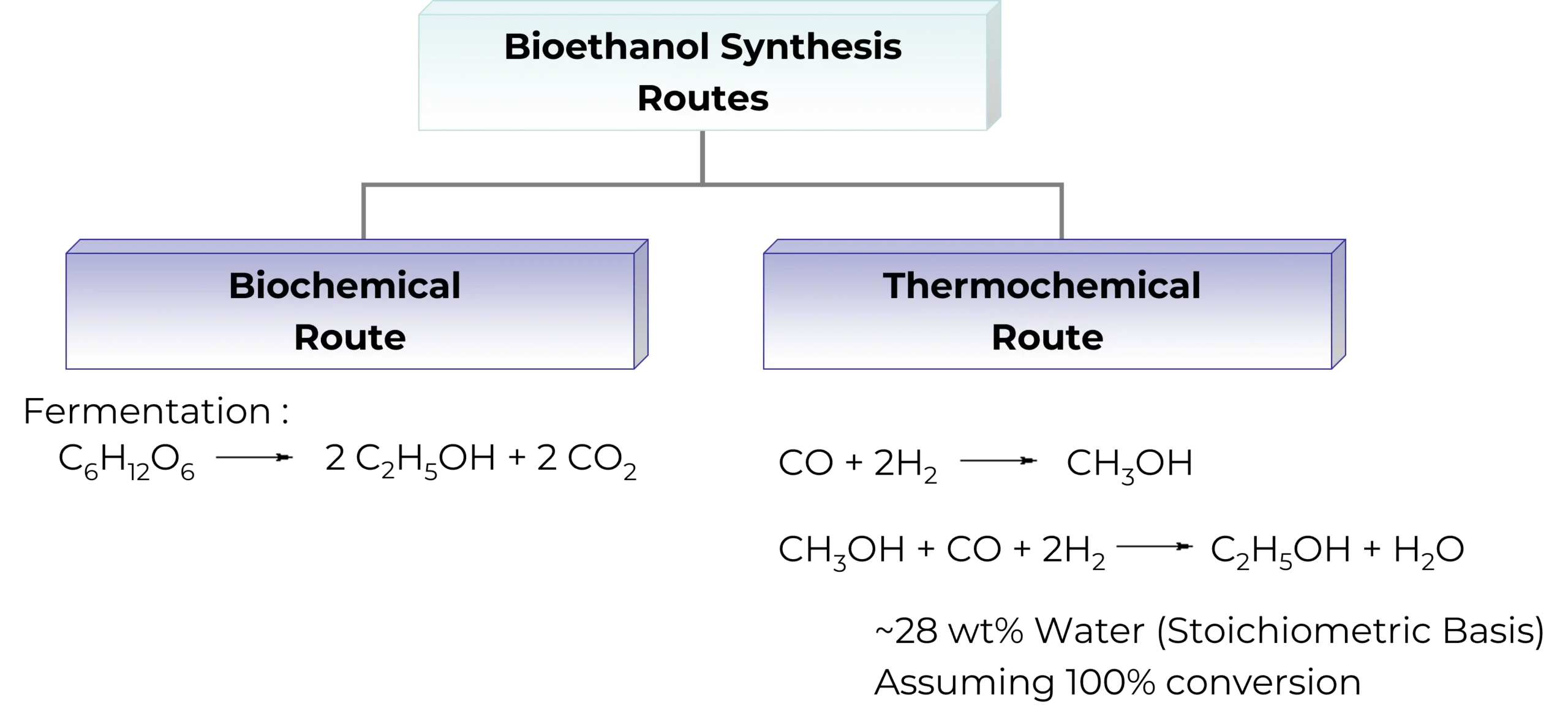

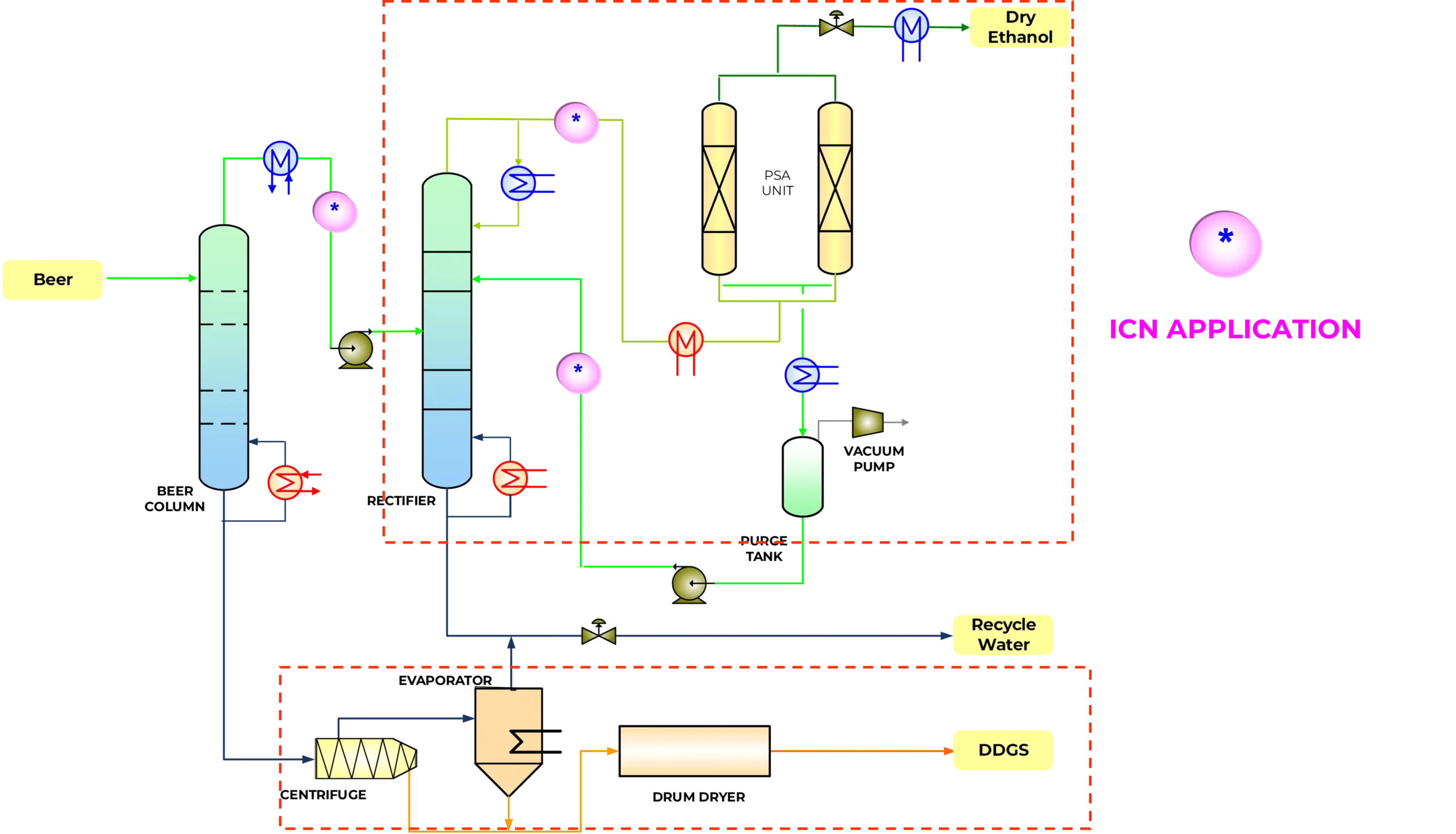

The Production of Bio Alkanols may be fermentation based or thermochemical route. In fermentation, the concentrations vary from 1.5% to typically 12% (depends on raw material, fermentation mechanism etc.). Conventionally, the Concentration of Ethanol is accomplished by costly and energy-intensive distillation and dehydration operations. Molecular sieves have essentially replaced azeotropic distillation due to their increased energy efficiency and resulting lower cost of production.

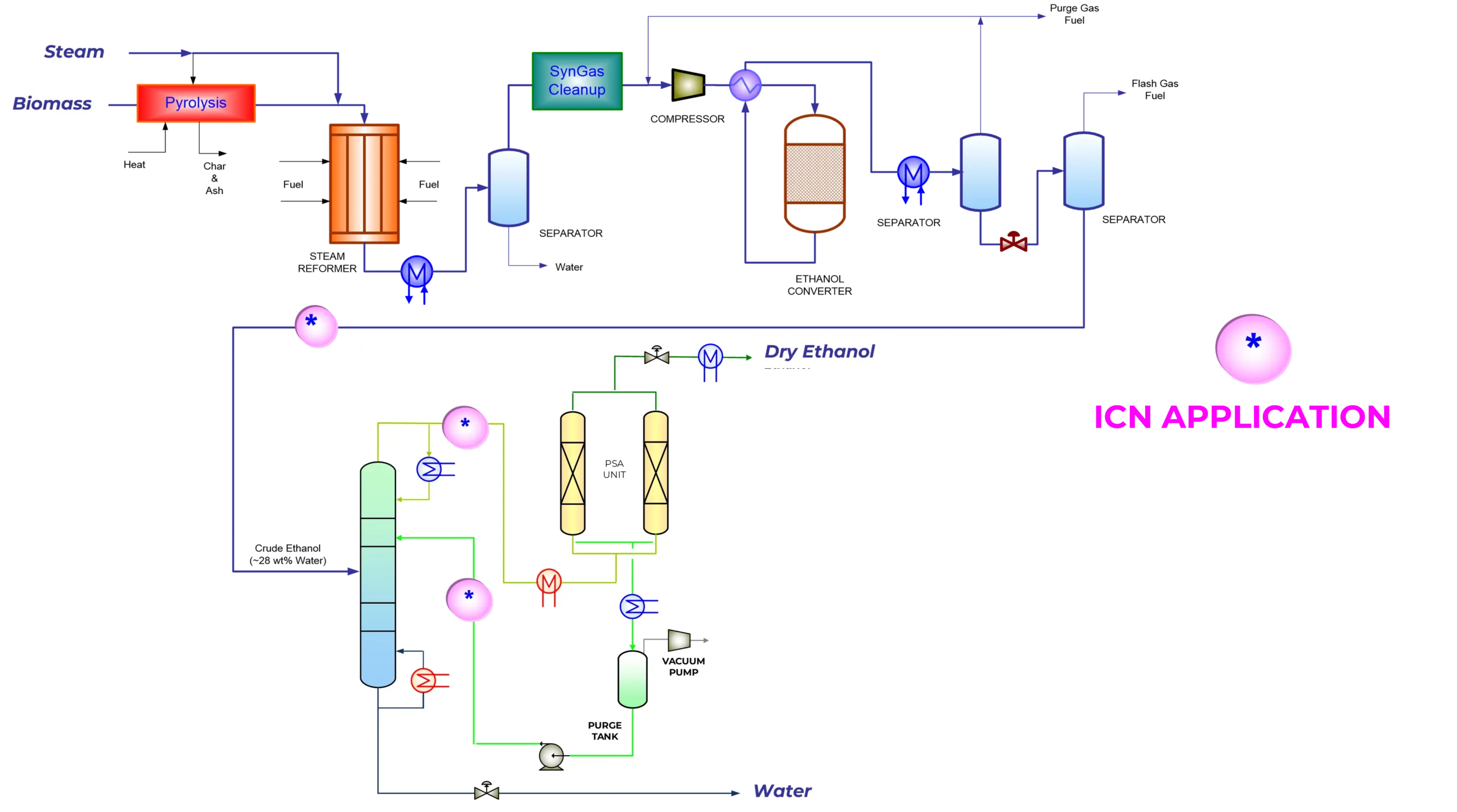

In thermochemical route, an alcohol rich stream with 20-30% water is produced. Conventional unit operations are energy-intensive and CAPEX intensive if energy consumption is reduced. ICN Membrane solutions are very attractive – both for green field and revamps.

We also offer low OPEX solutions for Methanol recovery and reuse in Biodiesel manufacturing.

Biochemical Route – MolSepTM Opportunities

Thermochemical Route – MolSepTM Opportunities

PETROCHEMICALS

MolSep™ Opportunities in Petrochemical Solvent Synthesis

In Petrochemicals manufacturing water may be used as a reactant and/or generated in the reaction. It is necessary to get rid of water in the final product. Removal of water also aids in other separations and purifications downstream of the reaction. Typically, distillation is used. However, due to the known limitations of distillation, ICN Membrane Solutions may be used for both green field applications and debottlenecking revamps. Economics are generally very compelling for revamps as both CAPEX and OPEX are typically lower.

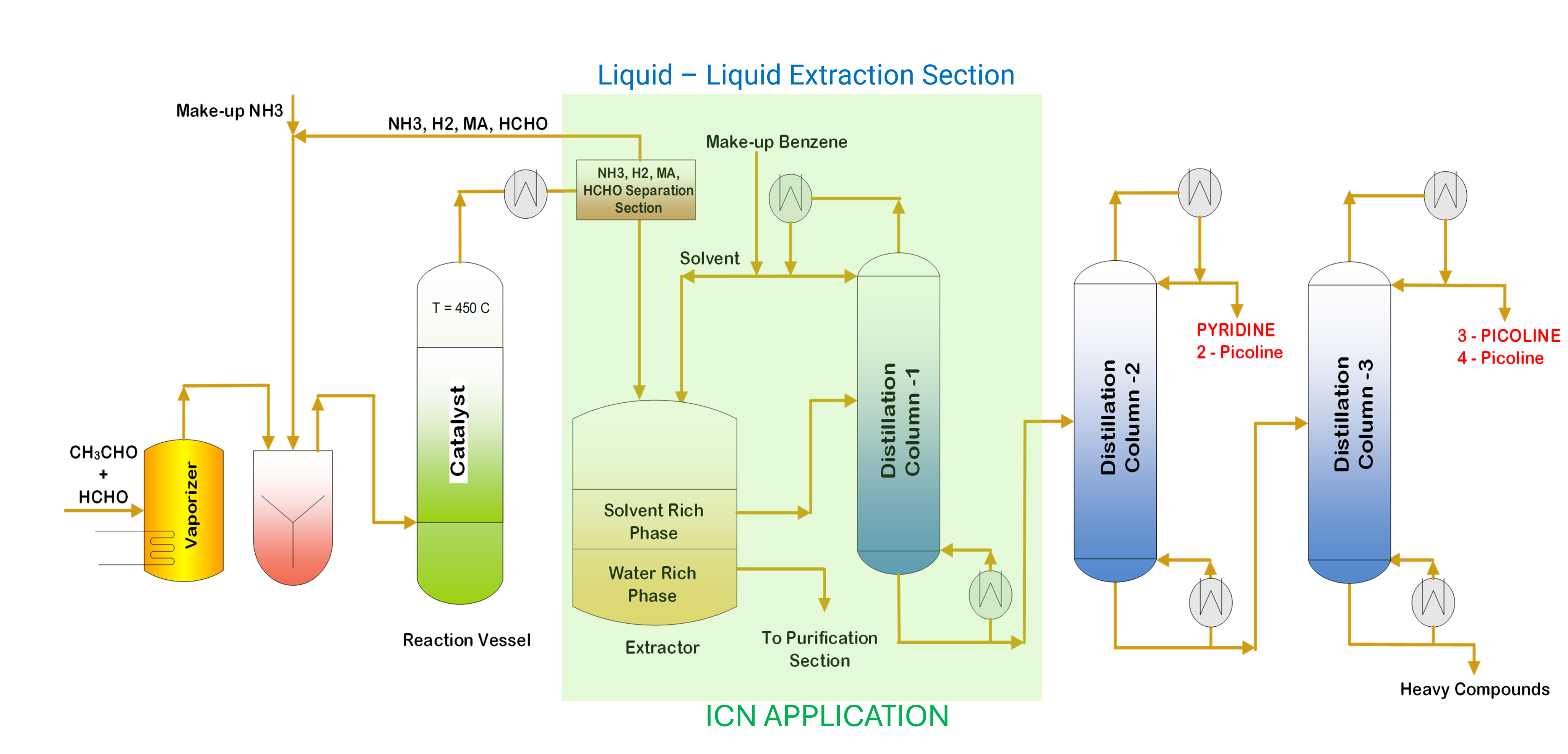

Some of the petrochemicals, wherein ICN VOLOPURE systems may be easily integrated are:

IPA (Propylene Hydration Process), Acetonitrile (Ammonolysis Process), THF (Dehydration of 1,4-Butanediol), Pyridine (Mobil Process) and Ethyl & Butyl Acetate, 1,4-Dioxane, Acrylonitrile, Ethyl & Butyl Lactate, Bisphenol A (BPA) among others.

Pyridine Production– MolSep™ Opportunities